Why Choose Us

- Home

- /

- Why Choose Us

tixamax adhesives & chemicals pvt ltd

Our Product Manufacturing Process

Step 1

We begin by understanding the specific needs of our customers, including tape type, size, color, custom prints and industry requirements.

Step 2

High-quality BOPP (Biaxially Oriented Polypropylene) films and strong adhesives are sourced to ensure durability, clarity and strong bonding performance.

Step 3

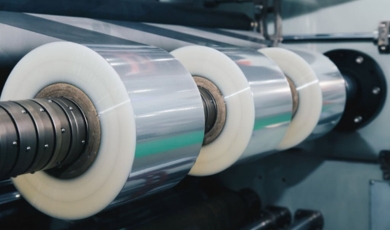

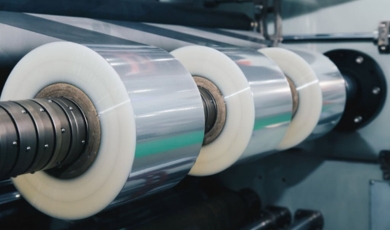

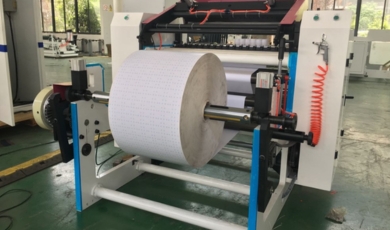

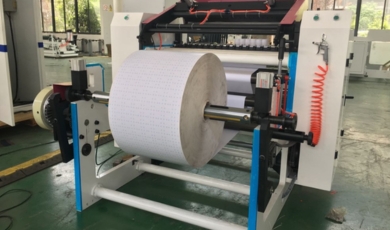

Using advanced machinery, the BOPP film is coated with a pressure-sensitive adhesive to achieve superior tackiness and bonding strength.

Step 4

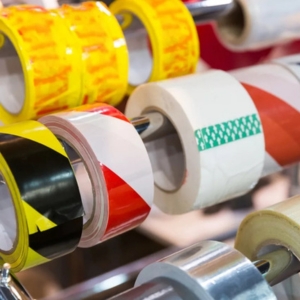

For custom orders, we apply logos, branding or specific designs using high-quality printing technology for a professional finish.

Step 5

The large jumbo rolls are slit into desired widths and lengths to meet customer specifications, ensuring precise dimensions.

Step 6

Every batch undergoes rigorous quality checks for adhesion strength, durability, print clarity and temperature resistance to meet industry standards.

Step 7

The finished tapes are securely packed to prevent damage during transit and are dispatched promptly to meet delivery timelines.

Step 8

We believe in building long-term relationships. Our team offers dedicated after-sales support to address any queries or concerns.

tixamax adhesives & chemicals pvt ltd

Why Tixamax is the Right Choice

Premium Quality

Strong adhesion, durability and tear resistance for secure packaging.

All Size Products

From transparent and colored tapes to custom-printed and jumbo rolls, we offer solutions for every need.

Cost Effective

High-quality adhesive technology that enhances productivity while reducing costs.

Customization

Custom-printed tapes help businesses enhance brand identity and visibility.